Products

Catalogue

You can review our catalog for more information about our products.

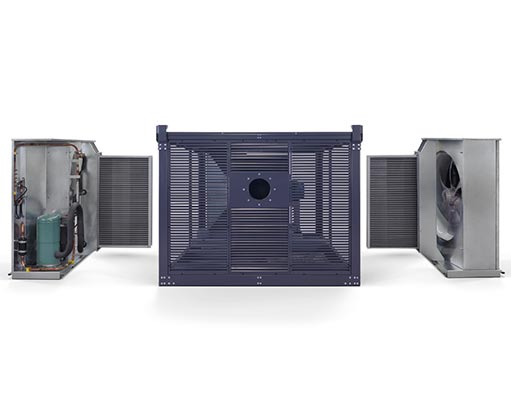

PCA Pre-Conditioned Air Units

Imbat PCA pre-conditioned air units provide climatization when the planes are parked and the engines are stopped. They provide up to 12.000 Pa static pressure and 100% fresh air while filtering the air through G4 and F7 class hygienic filters. Imbat PCA pre-conditioned air units are designed to operate in 35°C and with 100% fresh air conditions to have the supply temperature of 1°C. Imbat PCA pre-conditioned air units are compatible with BMS protocols with modbus communication system and therefore enable remote access and remote data saving. Units include main load seperator and high & low pressure transmitters as a standard.

Product Features

- R-410a refrigerant fluid

- Scroll compressor

- Inverter

- Cooling

- Plug fan

- Full automatic

- Electronic expansion valve

- LCD screen

- Compatibility for eco design criteria

- Filter alarm

- Easy of service and maintenance

- Check valve on the liquid line

- Hydrophilic or epoxy coated evaporator

- Hydrophilic or epoxy coated condenser

- Copper pipe, copper fin condenser

- Electric heater with steps

- Supply humidity sensor

- Smoke detector

- Control panel graphic interface

- BMS system integration with Lanwork or Bacnet protocols

- Remote acces through Ethernet with routers or Modbus

- Low or high pressure pressure switch

- High outdoor temperature

The design includes two individual cooling circuits and therefore makes it very easy to provide service and maintenance.

What Makes İmbat Different

Multi-Module Cooling

Imbat HORUS – PCA plane fresh air conditioning units have multiple modules and individual cooling circuits and therefore provide back-up opportunities.

Compact and Modular Design

Imbat HORUS – PCA plane fresh air conditioning units are designed with micro-channel condensers to be compact and modular.

High Efficiency

Imbat HORUS – PCA plane fresh air conditioning units are designed with inverter scroll type compressors, electronis expansion valves, variable speed high pressure radia plug fans and condenser fan speed control and micro-processor with an advanced software. The heat exchange surface on evaporator and microchannel condenser comes as a standard and has extremely high Energy effieincy when compared to it’s equavalents due to its maximized heat exchange surface.